3D printers forge face shields for fight against the coronavirus

Demand for face shields, along with N95-masks and other personal protective equipment (PPE) has increased during the Coronavirus pandemic.

Face shields help protect frontline-workers from potential virus-containing droplets released by coughing, sneezing and other close contact.

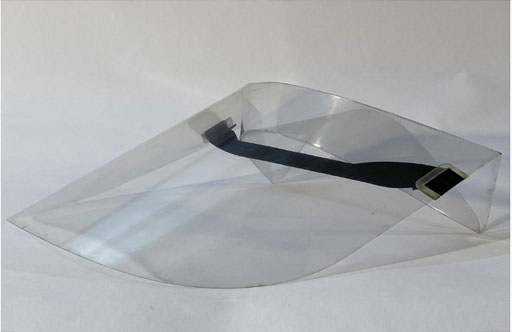

Protective Face Shield Masks are simple, transparent screens that cover the face and help prevent infectious droplets from entering the eyes, nose and mouth. They are usually worn in conjunction with masks or respirators, blocking splashes and sprays from reaching the face and making it preventing workers from touching their faces.

“Face shields are generally not used alone, but in conjunction with other protective equipment and are therefore classified as adjunctive personal protective equipment” .

Face shields are the easiest type of personal protective equipment (PPE) to make. They typically consist of just two parts: a visor that covers the face and which is usually made of plastics such as polycarbonate, propionate, acetate, polyvinyl chloride (PVC), and polyethylene terephthalate glycol (PETG); and a method of holding the visor in place, such as a headband or strap.